As renewable energy becomes a more dominant means of electricity generation, many analysts predict that energy storage deployments will significantly increase in the coming years. For example, Wood Mackenzie predicts that the global energy storage market “will surge to a 15-gigawatt annual market in 2024, even as system price declines slow down.” However, recent fires for lithium-ion battery energy storage systems (BESS), including one at the Arizona Public Service (APS) McMicken facility located just outside Phoenix, Arizona, have caused the industry to pause and reevaluate fire safety features for these installations. In taking a more in-depth look at BESS, one begins to see that a combination of core factors such as, battery chemistry, format, and capacity, creates a broad range of system classes. The result is that all BESS are not the same from a safety, functional, or an economical standpoint.

The first section of this article will examine a few of the key findings and observations gleaned from the APS McMicken facility investigation. Note that this article only focuses on investigation reports published by APS and LG Chem. Next, the second section will explore how new advancements in research and specific technologies are solving key challenges associated with lithium-ion batteries.

Key Findings from the APS Investigation

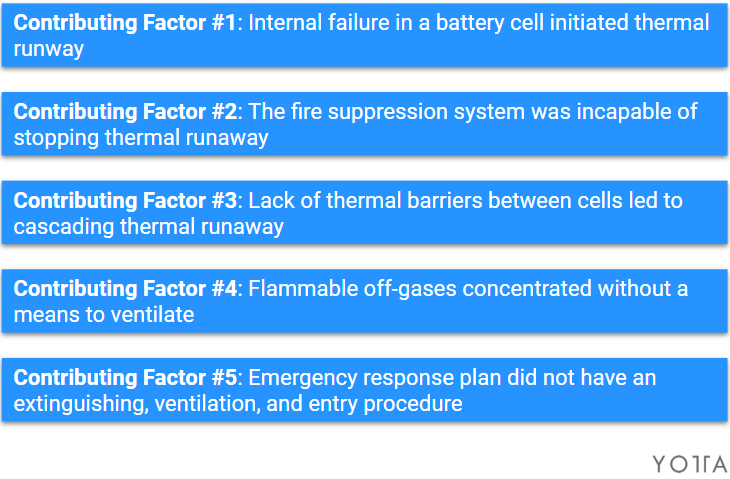

On July 27, 2020, APS, in a collaboration with DNV-GL, issued its consolidated and comprehensive technical report of the McMicken BESS event, which included recommendations for moving forward. Figure 1 provides a high-level overview of the contributing factors that led to the explosion at the McMicken BESS.

FIGURE 1: APS REPORT: CONTRIBUTING FACTORS LEADING TO THE INCIDENT

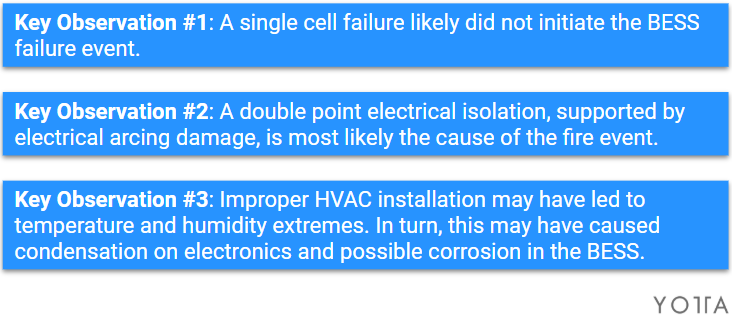

LG Chem issued its rebuttal in a report of findings for the McMicken BESS event authored by Exponent on July 30, 2020 (Swart, J., White, K., & Cundy, M.). It’s worth noting that Exponent has clearly indicated that its report summarizes the findings to date and is only meant “as a progress report since the investigation is ongoing” (Swart, J., White, K., & Cundy, M.). Figure 2 provides a high-level overview of Exponent’s key observations of the McMicken BESS event. While the initial root cause of the explosion remains to be seen, this article will take a closer look at contributing factors 1, 3, and 4 from the DNV-GL report and key observation 3 from the LG Chem report. These selected factors and observations will correspond with a later discussion on current alternative solutions and new technologies.

FIGURE 2: LG CHEM REPORT: SUMMARY OF KEY OBSERVATIONS THAT MAY HAVE LED TO THE INCIDENT

Contributing factor #1 leading to the incident was “an internal [battery] cell failure” (Hill, D.). Investigators noted that there were an abnormal amount of dendrites on “randomly selected battery cell samples without thermal damage taken from the [McMicken] BESS” (Hill, D.). A dendrite, or small metallic growth on a lithium-ion battery cell, can cause internal short circuits that may lead to thermal runaway, fires, and eventually explosions. Research has shown “that while Lithium dendrite initiation during battery charging may be inevitable...avoiding low temperatures thereby facilitating faster [Lithium] transport is critically essential in delaying dendrites” (Maraschky, A., & Akolkar, R.). The report concluded that the abnormal amount of dendrites present in the randomly selected battery cell samples caused the internal battery cell failure.

Lack of thermal barriers between cells was contributing factor #3. Without a thermal barrier, this led to a cascading vertical thermal runaway that eventually consumed the entire battery rack. The final investigation report notes that “it appears as though the materials and air gaps between [battery] racks prevented horizontal heat transfer and initiation of thermal runway in adjacent racks, resulting in only vertical propagation” (Hill, D.). These air gaps and physical breaks between racks appear to have helped prevent the complete BESS container from undergoing thermal runaway.

Lack of ventilation for the BESS was contributing factor #4. As the battery cells failed, they produced harmful, flammable gases that built up and had no way to escape the BESS. There were also no sensors inside the container to measure the flammable gas accumulation and alert emergency responders. This proved harmful for emergency responders when they opened the door to the BESS. The flammable gas concentration mixed with oxygen and the residual heat from the batteries undergoing thermal runaway. According to DNV-GL, that’s when the explosion occurred.

Finally, key observation #3 was tied to improper HVAC system installation. This may have led to temperature and humidity extremes, which caused condensation on electronics and possible corrosion in the BESS. According to Exponent, “[c]ondensation may result...in electrical arcing” while “corrosion may lead to...ignition of combustible materials if sufficient heat is generated at the connection” (Swart, J., White, K., & Cundy, M.). Further, according to Exponent, electrical arcing is most likely what caused the initial fire event that led to thermal runaway.

New Research Advancements & the Latest Technologies

Understanding BESS failures such as the one at the McMicken facility, has helped companies and researchers alike develop new materials and solutions for energy storage. For example, Yotta Energy’s PV-Coupled™ technology incorporates design features to address some of the concerns identified in the APS fire. First, PV-Coupled technology includes the SolarLEAF™, a panel-level energy storage solution that’s about the size of a briefcase. Yotta’s solution is built with Lithium-Iron-Phosphate (LFP) battery cells that have undergone fire testing in accordance with UL 9540A, Standard for Test Method for Evaluating Thermal Runaway Fire Propagation in Battery Energy Storage Systems. For the specific LFP battery cells used in Yotta’s solution, no fire or flames were observed during the thermal runaway testing.

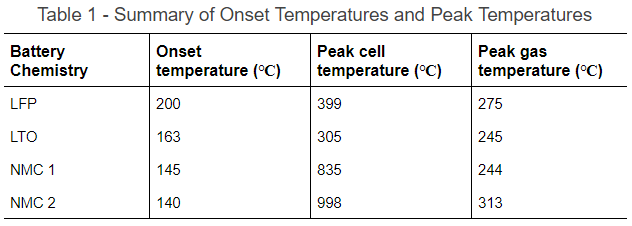

There are two recent papers that shed more light on LFP batteries and their performance when subjected to fire or high heat conditions. One recent study “focused on the quantification of toxic and flammable gases and heat generated during the thermal runaway” (Yuan, Dubaniewicz, Zlochower, Thomas, & Rayyan, 2020). They performed experiments with Lithium-ion cells of LFP, nickel manganese cobalt (NMC), and lithium titanate (LTO) battery chemistries. When each of the cells above was tested using an accelerating rate calorimeter (ARC), they found that the LFP cell had the highest onset temperature. However, the LTO cell had the lowest peak cell temperature. Further, the researchers noted that the “tests [results] confirmed that cells with an LFP cathode exhibited good stability under thermal abuse, while cells with an NMC cathode featured greater safety issues at high temperatures” (Yuan, Dubaniewicz, Zlochower, Thomas, & Rayyan, 2020). Please see Table 1 for a summary of the onset temperatures and peak cell temperatures for different cells. Researchers noted that the temperature results for NMC and LFP are consistent with prior experiments noted in published research.

TABLE 1 - SUMMARY OF ONSET TEMPERATURES AND PEAK TEMPERATURES

In a second report authored by Exponent, Inc. in collaboration with the Fire Protection Research Foundation and the Property Insurance Research Group, “small-to-large-scale free burn fire tests were conducted on Li-on” BESS composed of either LFP or NMC batteries (R. Thomas Long, J., & Misera, A. M.). The report notes that for all test scales BESS “comprised of LFP batteries exhibited a lower overall hazard…[h]owever, the effect of rack design, materials-of-construction, battery specifications and chemistry, and other design features are not well understood” (R. Thomas Long, J., & Misera, A. M.). Limited research exists on lithium-ion batteries and, while promising, more research is needed.

To avoid flammable gas build up, the SolarLEAF has a built-in vent to expel any gases and prevent any gas accumulation. Yotta’s solution is designed for the outdoors. It seamlessly fits under any industry standard solar module which allows for natural ventilation to the atmosphere.

Panel-level energy storage completely removes the need for an enclosed container with HVAC and fire suppression systems that traditional BESS require. Removing these systems from the BESS design and installation means eliminating additional potential failure points. Yotta’s solution also distributes energy storage over a larger area as opposed to concentrating a large number of Lithium-ion batteries in a small, enclosed container. Because Yotta’s solution distributes energy storage under solar modules, it also has inherent “thermal barriers” created by the physical distance between SolarLEAF units, as they are typically spaced one meter or more apart.

Finally, Yotta has patented and advanced thermal management to maintain an optimal temperature range for the batteries between 10 degrees C and 38 degrees C, even in extreme environments. Maintaining this optimal temperature range could prevent dendrites from forming in the batteries. It also extends the average life of the batteries to match the life of solar modules. Further, the advanced thermal management works throughout the day to prevent overheating or freezing.

In addition, there is research being done on lithium-ion batteries. Researchers at Berkeley Lab and Carnegie Mellon University recently announced that a new solid-state battery design could increase overall battery life and improve safety. In a news release from Berkeley Lab, researchers discovered “a new class of soft, solid electrolytes...that suppress dendrites in that early nucleation stage, before they can propagate and cause a battery to fail.” This finding is critical to ensuring stable battery performance over its lifetime especially during charge and discharge cycles.

24M Technologies is one company commercializing these soft, solid electrolytes, building on the joint research from Berkeley Lab and Carnegie Mellon University. They have developed a lithium-ion cell using SemiSolid electrodes, or soft polymers of intrinsic microporosity (PIMs) that reduces costs and maintains safety. To address the issue of flammable gases created by thermal runaway, New York City requires remote sensing to monitor and identify harmful gas accumulation in BESS. Gas detection systems such as Li-on Tamer Rack Monitor 2.0 by Nexceris, LLC are designed to monitor and provide an early warning for any possible lithium-ion battery failure.

Achieving Carbon-free Goals with Safe Energy Storage Alternatives

Despite the fire at the McMicken BESS facility, Arizona Public Service is still committed to being 100 percent carbon free by 2050. In an interview with Greentech media, Scott Bordenkircher, Director of Technology Integration and Innovation, emphasized this point by saying “You can’t get there with intermittent resources that only generate during daylight...We know [storage] is the answer to how you get to a clean energy commitment like that.” Innovative energy storage solutions, such as Yotta’s PV-Coupled technology, are examples of what we’ve learned from and how we’ve improved upon prior generations of BESS. Although this article has only touched upon a few differences in BESS classes, continued technological advancements are making safer BESS solutions a reality in the near term. The hope is that with safer BESS solutions we can exceed current analyst predictions for solar plus storage deployments and achieve ambitious zero-carbon emissions goals in the near future.

Resources

Hill, D. (2020, July 18). Technical Support for APS Related to McMicken | McMicken Battery Energy Storage System Event Technical Analysis and Recommendations | Arizona Public Service. Retrieved from Arizona Public Service - DNV GL Report: https://www.aps.com/-/media/APS/APSCOM-PDFs/About/Our-Company/Newsroom/McMickenFinalTechnicalReport.ashx?la=en&hash=50335FB5098D9858BFD276C40FA54FCE

Maraschky, A., & Akolkar, R. (2020, March 18). Temperature Dependence of Dendritic Lithium Electrodeposition: A Mechanistic Study of the Role of Transport Limitations within the SEI. Journal of The Electrochemical Society, 167(6). doi:https://doi.org/10.1149/1945-7111/ab7ce2

R. Thomas Long, J., & Misera, A. M. (2019). Sprinkler Protection Guidance for Lithium-Ion Based Energy Storage Systems. Bowie: Fire Protection Research Foundation, an affiliate of the National Fire Protection Association. Retrieved August 9, 2020, from https://www.nfpa.org//-/media/Files/News-and-Research/Fire-statistics-and-reports/Suppression/RFESSSprinklerProtection.pdf

Stromsta, K.-E. (2020, February 24). WoodMac: Global Energy Storage Installations to Hit 15GW by 2024 | The 2020s are the decade when the energy storage market comes of age—with potentially profound implications for the global energy system. Retrieved from WoodMac: Global Energy Storage to Hit 15GW by 2024 | greentechmedia.com: https://www.greentechmedia.com/articles/read/woodmac-global-energy-storage-installations-to-hit-15gw-by-2024

Swart, J., White, K., & Cundy, M. (2020). APS McMicken Progress Report. Phoenix: Exponent. Retrieved August 25, 2020, from https://docket.images.azcc.gov/E000007939.pdf

Yuan, L., Dubaniewicz, T., Zlochower, I., Thomas, R., & Rayyan, N. (2020, December). Experimental study on thermal runaway and vented gases of lithium-ion cells. Process Safety and Environmental Protection, 144, 186-192. doi:https://doi.org/10.1016/j.psep.2020.07.028

About the Author

Jennifer G. Gallegos is the Director of Research & Strategy at Yotta Energy, a renewable energy company based in Austin, Texas, that’s reimagining the way the world stores and uses solar energy. As a licensed professional engineer in Texas, she has over 10 years’ experience in project management, commercial building design, sales, and marketing.